0512-62380743

/

1377 1886 689

0512-62380743

/

1377 1886 689

0512-62380743

/

1377 1886 689

0512-62380743

/

1377 1886 689

Suzhou Zhiguan Yisheng Information Technology Co., Ltd. has been committed to the Internet of Things since its inceptionRFIDResearch and implementation of industry application technology. For years of service1000+Home to all types of customers.

With the rapid development of e-commerce, Internet platforms and other fields, the material management of warehousing and circulation links is facing new challenges. The speed of material circulation will put forward higher requirements on the basis of the original, and the traditional storage management mode can not meet the rapid development of modern logistics.RFIDHandheld terminal The equipment will greatly improve the current high-demand warehousing and logistics management, which is of great significance. It saves human resources, speeds up the flow of materials, improves efficiency, and realizes the construction of modern warehousing and logistics management. RFIDHandheld terminal The equipment allows warehousing logistics management to accelerate the information construction.

Warehousing has always played the most important role in the logistics system. With the rapid development of modern logistics, higher requirements have been put forward for warehouse operations such as warehousing, warehousing, shifting, inventory and goods inquiry. Modern warehouse storage is not only to complete the simple batch processing of goods in and out, but also to make clear database records of the types, quantities, production attributes, palletizing and other information of the goods in the warehouse. In order to obtain accurate goods data and supply chain information at each stage of the logistics link.

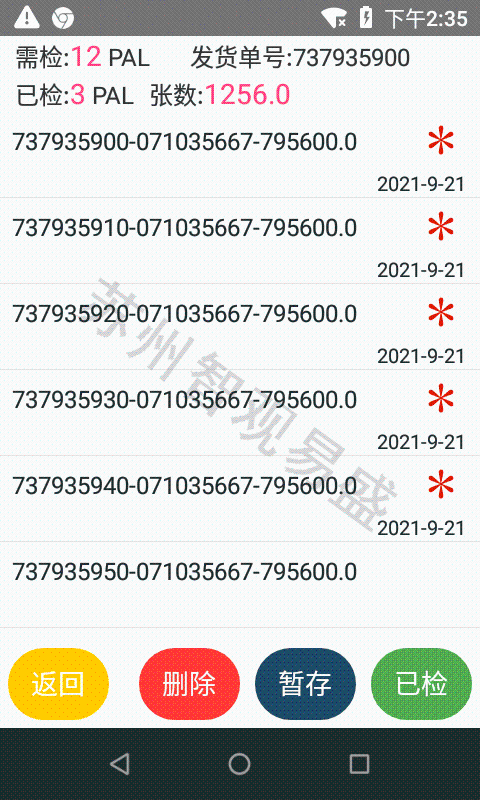

RFIDHandheld terminalAs a widely used information equipment in the logistics industry, it can be directly usedRFIDElectronic label input scanning, to cope with a large number of goods in and out of the warehouse, greatly improve the warehouse throughput efficiency;Ensure the accuracy and reliability of the input data, without manual recording, directly use bar code scanning for goods in and out of the warehouse registration and inventory;Help enterprises reduce the labor cost input of logistics warehousing system and obtain higher returns.

Warehousing management: It is used for each entry of goodsPDAHandheld scan, record in the database;

Outbound management: Scan the outbound bar code, automatically display the name of the goods, storage location, check and confirm;Shift management: When the goods are moved from one location to another, they are automatically recorded in the database by scanning the barcode through the handheld machine;

Inventory management: withPDAAfter scanning the storage space, the handheld machine will automatically display the name of the goods, quantity, etc., and then scan the barcode to confirm whether the goods are in the storage space;

Cargo search: the operator enters the cargo number on the mobile phone, and the storage location and bar code of the goods are automatically displayed.

RFIDSmart handheld terminal is a kind ofRFIDRadio frequency technology and data terminal integration of wireless portable equipment. With large capacity storage, long service time, a variety of communication and expansion interfaces The hardware module can be selected according to different needs, and the software can be fully customized according to user needs, etc., which is widely used in the warehousing management of inventory, materials shelves, inventory points, materials out of the warehouse, retrieval and query. Solved the material search, time-consuming and laborious. Realize quick inventory counting and shorten the time of inventory management personnel. It is time-consuming and prone to material and quantity errors when entering and leaving the warehouse.

The smart terminal carries itself RFIDtag Read and identification module and powerful processing and storage functions, the use of wireless network environment, with the background of warehousing management software, to achieve accurate statistics of the number of materials, storage location, accurate management of each material into and out of the warehouse process. To realize the information, scientific and accurate storage management. This is undoubtedly a very big medicine for enterprises, inventory will save a lot of manpower, time costs, but also improve the management of various efficiency levels.

Why did the introduction of a costly fixed asset system end in failure? No matchingRFIDEquipment, too time is not clear, but can not count the assets that are out of reach, asset managers do it and give up. Why buy and useRFIDEquipment, still can not achieve quick inventory operation? Different application scenarios for labels, collection equipment selection are very sophisticated, yesRFIDLack of understanding of the features, inaccurate matching, instead.....

The view of wisdom is easyRFIDWarehouse management system products or raw materials have a clear identity binding, which can effectively improve the efficiency and accuracy of sorting and shipping Remote data reading without manual inventory, improve inventory turnover and warehouse utilization.

According to the statistics of the National Archives Administration, by2008The national archives warehouse area is285.610,000 square meters, and the archives are25284.5manmaki;There are also all kinds of audio and video files, electronic files based on disk discs, microfilm files, etc. And every year, the archives warehouse also undertakes a large number of archives into the library storage tasks, most of the archives warehouse is close to saturation...